Feb 01 | 2021

Imported cutting machine for spent fuel rods misidentified in customs documentation

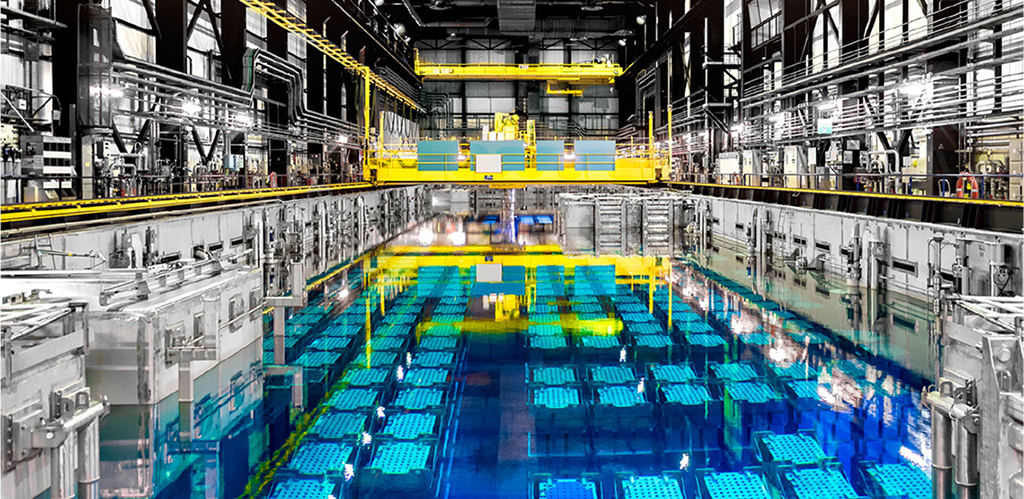

During the period when many nuclear power plants were being constructed as the forecasted solution to produce clean and inexpensive power a large company contracted to build a facility to recycle fuel rods that had been replaced in operating nuclear power plants. The reasoning was that instead of storing spent uranium in the fuel rods that takes many years to no longer be radioactive it could be recycled and used again. After five years of generating power 90 percent of the potential energy remains. The processing plant’s function was to cut the fuel rods into small lengths and remove the fissionable materials (94 percent uranium) for reprocessing for power generation and other uses such as for medical equipment.

During construction a sizeable purchase order was awarded to a French company to supply machinery that would cut the fuel rods. The order included design elements as well as fabrication and delivery to the jobsite in the U.S. After delivery to the jobsite, U.S. Customs cited us for incorrect duty classification under the former Tariff Schedules of the U.S. This included reclassification with a higher rate of duty plus a fine. In addition, the fine was for not paying duty on the engineering and drawings produced in France. Project management was very upset about this and looking for a resolution. This was also important as the cost of the extra duty and fine would have to be borne by us, the contractor.

In a meeting with project management I described a plan to convince Customs to drop the charges and fine. I explained that the French company used a description of the material that was not accurate. Customs classified the machine as a “metal cutting” machine and that was not accurate. A more accurate description was “metal working” with sub-wording more accurately describing its purpose including producing scrap metal and not finished components.

I arranged for a Customs official in Washington, D.C. to meet me at the jobsite along with the project manager to discuss the situation and see if the machine could be reclassified to its proper description. A client representative was also invited to attend. The meeting was held shortly thereafter and after our presentation to the Customs official he wrote “dismissed” on the citation much to the relief of project management. However, the small duty and fine for the engineering and drawings produced in France remained. This was not contested.

The lesson learned is one that has always been common during a major construction project. Many departments are involved during the engineering, procurement and construction phases of the project. All too often important items are overlooked and often involve logistics related areas. Attention must be given to all aspects of the regulations of Customs and other Government agencies. These days many companies have compliance officers that oversee this process so that delays and fines can be avoided.

About the Author

John Amos is an international logistics and transportation consultant specializing in issues related to planning, operations and regulatory issues. His experience encompasses the fields of ocean, air and surface transportation. For more than 45 years he has had international and North American positions in the fields of logistics, procurement and construction management.

John Amos is an international logistics and transportation consultant specializing in issues related to planning, operations and regulatory issues. His experience encompasses the fields of ocean, air and surface transportation. For more than 45 years he has had international and North American positions in the fields of logistics, procurement and construction management.He is spearheading the Breakbulk Veterans guest author program. If you have a story to tell, contact John at [email protected].

Subscribe to BreakbulkONE and receive more industry stories and updates around impact of COVID-19.