Nov 23 | 2020

Jones Act, vessel supply solutions and training

|

Industry Acronyms to Know

|

Following up on our U.S. Offshore Wind Projects webinar held earlier this month as part of the Breakbulk Americas Digital Special, panelist Jonathan Zier from Crowley answers additional viewer questions that we didn’t have time to address during the session, primarily around the Jones Act and how it will affect development of this promising energy sector.

How do EU transport/installation and other companies get involved in US offshore wind projects, considering Jones Act compliance?

Crowley: There will be a lot of heavy-lift cargo such as the monopiles and WTG components delivered from Europe and Asia onboard non-US flag heavy lift vessels. The Jones Act comes into play when shuttling the components offshore to the installation vessels. I think there will be other opportunities for EU companies to partner with Jones Act owners/operators on SOV and CTV vessels.

How difficult would it be for the U.S.-flag vessel industry to replicate a fleet of installation vessels like that already seen in Europe?

I don’t really think the fleet in Europe will be fully replicated in the US. I believe the fleet that will be developed in the US will have to be tailored to the challenges we face over here—especially that shuttling concept. This is not as much of an issue in Europe as it is here in the US. I believe the early projects will start out by using the current existing Jones Act fleet in the market, maybe with some slight modifications, and then once the market starts to take off in the US, there will be more purpose-built JA assets produced. The key question is what shuttling concept will the industry accept? If newbuilds will be required, the clock is ticking, and construction contracts will have to be made relatively soon.

What are the concerns within the industry for the Jones Act fleet to satisfy the projected vessel demand for US offshore farm installation?

Currently, almost all owners with assets that can support offshore wind are focusing primarily on that. The U.S. Gulf of Mexico (GOM) offshore oil & gas market is down and projects are sliding just like everything else. But, that’s not to say those projects will not be executed.

We will have to balance vessel availabilities in the market between oil & gas and wind, i.e., GOM and US East Coast (USEC). The potential for spot market availabilities for wind in USEC, as there currently are in oil & gas in GOM will not be a workable solution going forward, which is one challenge.

Another challenge of course is capital. If we are talking vessel modifications for the installation phase, that’s low capital, relatively speaking, that we feel can be shared between owners and developers. Jones Act compliant SOVs on the other hand will be very capital intensive, and we believe that it could be advantageous to partner with existing European owners who already have experience in this field to obtain lower design, construction and operational costs.

Has Crowley launched a vessel specifically dedicated for offshore wind turbine installation work?

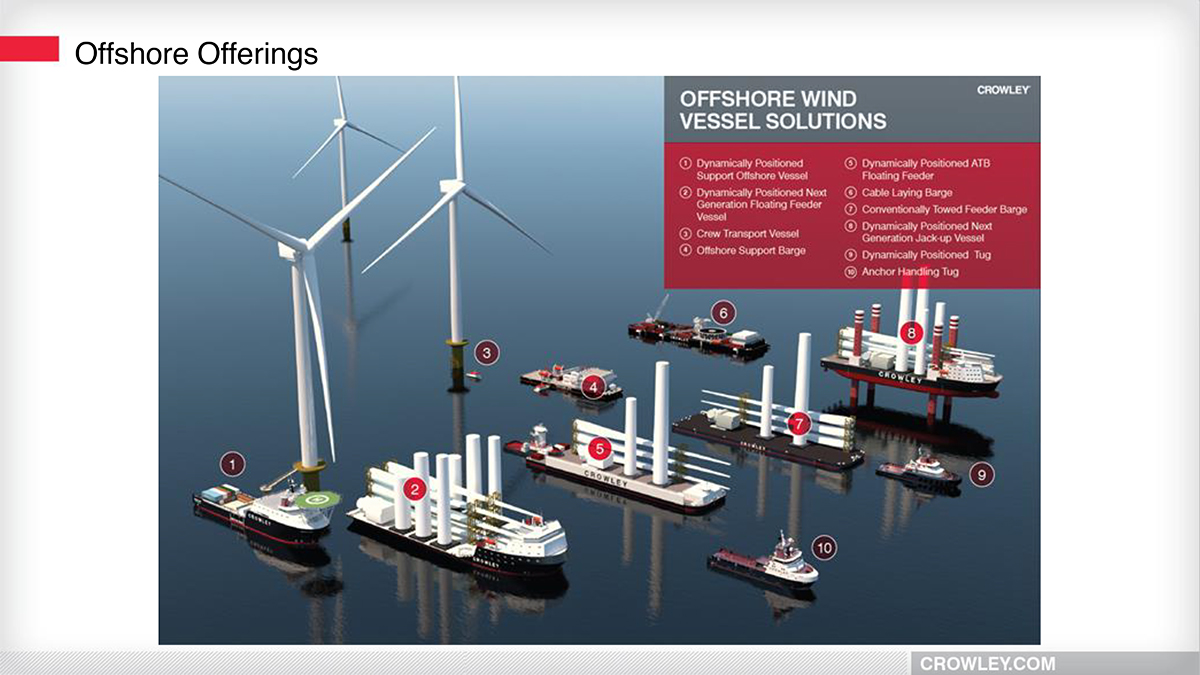

We have developed a DP ATB wind turbine shuttle concept that we feel could currently be the best solution to this issue. We also have put in work to design a Jones Act jack-up feeder barge, or even a jack-up feeder ship, but of course both of these options are much more expensive and will need to be new-builds.

The ATB concept can be developed by modifying current existing assets. We have also made a case for the WTG feeder using traditional tug and barges, as is done in the GOM. Our engineers have calculated vessel and cargo motions and we have provided all of this data to the major OEMs. Now it’s really up to them the determine what will be the best and most cost-effective solution, and we will continue to support them in that regard.

How is Crowley training its crews to prepare for offshore wind farm work?

Very recently we held a two-day symposium with our operation team, commercial team and several of our senior captains and officers to discuss this very matter. Our crews are already very experienced supporting offshore GOM oil and gas work. But offshore wind poses some additional unique operational challenges: high op tempo, multiple personnel transfers offshore, coordinating landings with jack-up vessels and damage prevention, and let’s not forget to mention the delicate nature of WTG cargo.

Some of the ideas that came about include a walk-to-work or personnel transfer system from the offshore stand-by tug to the shuttle barge to transfer personnel for making up assist tugs and mooring to the installation vessel. This is a much safer method than transfer by a recessed barge ladder. Another innovation is remote seafastening for WTG components to be released without the need for any crew standing near the cargo. Finally, as Crowley is the largest employer of U.S. mariners, we are approaching maritime academies throughout the United States to work with them on increasing the awareness of the industry and possibly developing an offshore wind curriculum so that future mariners will be ready for this industry.

About the author

Jonathan Zier is the Manager of Business Development for Crowley’s offshore services. He is responsible for sales and chartering activities of Crowley’s unique Jones Act offshore fleet, primarily consisting of DP-capable high bollard pull offshore tugs as well as the largest U.S.-flagged fleet of 400-foot flat deck project barges. With over 20 years of experience in the project cargo and offshore sectors, Jonathan has served previously as Head of Operations at Boskalis (formerly Dockwise), managed business development for the Americas at Hansa Heavy Lift, and as President of the Americas for dship Carriers.

Jonathan Zier is the Manager of Business Development for Crowley’s offshore services. He is responsible for sales and chartering activities of Crowley’s unique Jones Act offshore fleet, primarily consisting of DP-capable high bollard pull offshore tugs as well as the largest U.S.-flagged fleet of 400-foot flat deck project barges. With over 20 years of experience in the project cargo and offshore sectors, Jonathan has served previously as Head of Operations at Boskalis (formerly Dockwise), managed business development for the Americas at Hansa Heavy Lift, and as President of the Americas for dship Carriers.Jonathan graduated in 2000 from the United States Merchant Marine Academy in Kings Point, N.Y. with a deck officer’s license, and a bachelor’s degree in marine transportation with a minor in marine engineering. Upon graduation, he began his career sailing as a deck officer for several years with Military Sealift Command.

Subscribe to BreakbulkONE and receive more industry stories and updates around impact of COVID-19.