Leading Shippers Offer Sneak Peek Into Groundbreaking “Module360” Project

By Simon West

Get ready to explore the future of modularization at Breakbulk Middle East! Ahead of their highly anticipated workshop in Dubai, industry leaders Daniel Duus (global head of logistics, thyssenkrupp Uhde), Sebastian Krey (lead transport engineer, dteq Transport Engineering Solutions), and Dr. Sven Hermann (managing director, ProLog Innovation and professor for logistics and supply chain management at NBS Northern Business School) offer a sneak peek into their groundbreaking “Module360” innovation project.

From Issue 1, 2025 of Breakbulk Magazine.

(3-minute read)

Daniel, what does the world of modularization and standardization look like at thyssenkrupp Uhde today and in the future?

.jpg) At thyssenkrupp Uhde, modularization and standardization in plant construction projects are key priorities aimed at boosting efficiency and cutting costs. These aspects, which are a fundamental part of our company’s strategic orientation, are particularly crucial in a market increasingly driven by demands for faster project timelines, greater flexibility and more cost-effective production. We are currently developing modular solutions through our standardization projects in order to reduce project complexity. The advantage is obvious: by prefabricating modules in controlled environments, construction times on site can be significantly reduced, which in turn lowers overall costs and risks. In addition, our customers are increasingly demanding modularized systems, especially in regions where assembly costs are very high and capacities are scarce, such as the U.S.

At thyssenkrupp Uhde, modularization and standardization in plant construction projects are key priorities aimed at boosting efficiency and cutting costs. These aspects, which are a fundamental part of our company’s strategic orientation, are particularly crucial in a market increasingly driven by demands for faster project timelines, greater flexibility and more cost-effective production. We are currently developing modular solutions through our standardization projects in order to reduce project complexity. The advantage is obvious: by prefabricating modules in controlled environments, construction times on site can be significantly reduced, which in turn lowers overall costs and risks. In addition, our customers are increasingly demanding modularized systems, especially in regions where assembly costs are very high and capacities are scarce, such as the U.S.

Modularization also offers the opportunity for forward-looking business models and sustainable industrial processes – sustainability and the circular economy are key future trends in the industry. Modularized systems comprising standardized components can, in many cases, be better adapted to future requirements, or more easily dismantled and recycled at the end of their service life. This could become a significant competitive advantage in the coming years, especially in view of stricter environmental regulations and the increasing importance of green technologies.

Let’s move on to the “Module360” project. Why did you set up the project with selected logistics partners and what specifically do you expect to gain from it?

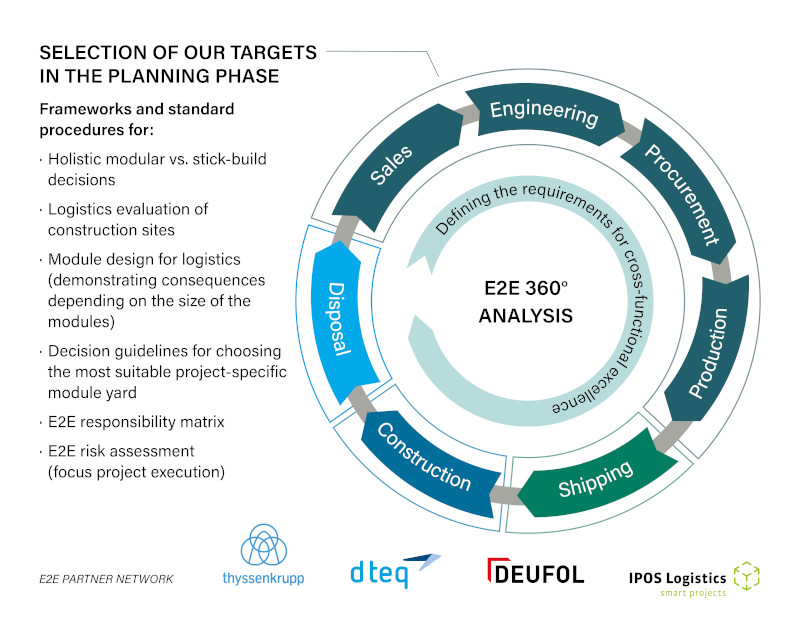

In this project, we deliberately chose a consulting company, a packaging firm and a transport engineering specialist. Its goal is to develop a well-founded E2E (end-to-end) concept study that contains a guideline for holistically optimized E2E planning and handling of future thyssenkrupp Uhde projects in the field of modularization. It also provides a basis for the partners for comprehensive E2E consulting, planning and handling of other industrial projects. The intended results are particularly concerned with the identification and evaluation of drivers, risk factors and influencing factors, as well as a practically applicable guideline for optimal project management, especially with regard to standardization, process reliability and quality, sustainability, and costs.

Thanks to this concept study, thyssenkrupp Uhde will have a guideline in logistics that we can use for future modularization projects across all project life cycles. It’s increasingly important for logistics to be involved in projects as early as possible and to play a greater role in shaping them in order to have planning security from the outset and to be able to generate significant benefits during the project term, such as avoiding NC (non-conformity) costs, increasing OTD (on time delivery), optimizing logistics costs, minimizing existing risks in the supply chain and integrating sustainability aspects.

Sebastian, in terms of challenges, what additional logistical challenges do modularization projects entail? And would you also say that modularization projects generally lead to higher logistics risks?

_1.jpeg) The biggest logistical challenges result from the size and weight of the modules. The demands on infrastructure such as ports and roads, as well as on equipment and transport carriers, rise sharply with large cargo sizes. Modular transports enable precise planning, allowing for careful selection of the necessary trailer, determining suitable roads and deciding whether the load should be lifted or transported on wheels. While logistical risks such as delays or customs clearance issues remain similar, modular transports present additional technical challenges. However, with detailed planning, these risks can be reduced to a level comparable to standard container transport. An important step in this process is the close collaboration between the engineers at the manufacturing companies who develop the modules and the engineers at the logistics firms.

The biggest logistical challenges result from the size and weight of the modules. The demands on infrastructure such as ports and roads, as well as on equipment and transport carriers, rise sharply with large cargo sizes. Modular transports enable precise planning, allowing for careful selection of the necessary trailer, determining suitable roads and deciding whether the load should be lifted or transported on wheels. While logistical risks such as delays or customs clearance issues remain similar, modular transports present additional technical challenges. However, with detailed planning, these risks can be reduced to a level comparable to standard container transport. An important step in this process is the close collaboration between the engineers at the manufacturing companies who develop the modules and the engineers at the logistics firms.

Challenges often arise around load securing or ensuring the structural integrity of the load during transport. Changes in dimensions or weight can significantly affect the availability of the transport carriers. Deck carriers, for example, are less available and more costly than standard MPP vessels. As a result, we recommend that our customers consider the entire process – from selecting the production site to final installation – early in the planning stage.

Sven, what can participants expect at your “Discover the Future of Modularization” workshop at Breakbulk Middle East?

_1.jpeg) In our interactive workshop, we will focus on key project questions during the planning phase (see Graphic: Scope of Project Module360). How can we make more informed, holistic decisions regarding modular versus stick-build construction from a logistics perspective? What criteria catalogs will we use in the future to make more comprehensive and optimal decisions for yards and construction sites? What approaches and tools are available for E2E risk management, particularly during project execution? And how can we better utilize lessons learned across companies? Our project partners Deufol and IPOS Logistics will also be present to facilitate discussions, especially with EPCs interested in exploring the future of modularization.

In our interactive workshop, we will focus on key project questions during the planning phase (see Graphic: Scope of Project Module360). How can we make more informed, holistic decisions regarding modular versus stick-build construction from a logistics perspective? What criteria catalogs will we use in the future to make more comprehensive and optimal decisions for yards and construction sites? What approaches and tools are available for E2E risk management, particularly during project execution? And how can we better utilize lessons learned across companies? Our project partners Deufol and IPOS Logistics will also be present to facilitate discussions, especially with EPCs interested in exploring the future of modularization.

Discover the Future of Modularization will take place in Breakbulk Middle East’s Futures Hub on Tuesday, February 11 from 10:15am-11:45am.

thyssenkrupp Uhde and dteq Transport Engineering Solutions are members of the Breakbulk Global Shipper Network, a worldwide group of shippers involved in the engineering, manufacturing and production of project cargo.