Sep 12 | 2023

MPVs Ready to Take the Next Electric Step

By Carly Fields

Irregular port calls and a lack of funding have seen MPV operators hold back from committing to shore power connections on board. However, climate-conscious operators and secondary ports are showing the sector that it is time to step up to the shore power plate! News editor Carly Fields investigates in a feature from Issue 5 of Breakbulk Magazine.

Ports are facing growing pressure to manage and reduce the carbon footprint associated with vessels calling at their berths – and that includes multipurpose and heavy-lift ships.

While most efforts to tackle emissions are centered on enhancing ship-based efficiencies – an aspect beyond the control of ports – one effective approach is the integration of shore-based power supply with ports taking on the role of green energy generators and suppliers.

The utilization of ship shore power is already a proven technology that holds promise. Connecting ships to electricity grids while they are docked at ports can swiftly and significantly reduce local air pollution caused by ships at berth. Moreover, it contributes to the reduction of greenhouse gas emissions through lower fuel consumption.

Successful shore power implementation can be seen in the ports of California. These ports have long implemented strict regulations aimed at minimizing emissions during vessel berthing and compliance with these regulations has spurred the wider adoption of shore power systems.

China has also taken steps to endorse shore power solutions as a strategy to cut emissions within its ports and urban areas. Starting in 2019, new domestic vessels in China are mandated to be equipped for shore power compatibility. It’s anticipated that Europe will follow suit by introducing more stringent regulations related to port emissions, further expediting the global acceptance of shore connection systems.

Yet MPVs and heavy-lift ships are behind the curve in installing the necessary infrastructure to allow them to plug in at shore power-ready ports.

SAL’s Shore Power Plunge

Heavy-lift MPV operator SAL Heavy Lift is believed to be the first MPV operator to have committed to shore power infrastructure on its newbuild vessels. Its Orca class are zero emission, methanol ready vessels, with 2 x 800 t fully electric cranes, a ship-to-shore power connection and shore power supply on deck for its client’s equipment.

Scheduled for delivery from mid-year 2024, the first two ships will be exclusively involved in the transportation of offshore wind turbine components in a long-term commitment with Siemens Gamesa Renewable Energy. Two additional sister vessels are scheduled to enter the premium heavy-lift shipping market in the first half of 2025.

Jakob Christiansen, head of research and development, retrofit and newbuilding at SAL Heavy Lift, said that including shore power in the newbuilds was an obvious choice. “With an ambitious and environmentally friendly ship concept like the Orca class, there is no question that we will use shore power in the port to reduce emissions and noise in the port. We also strongly believe that shore power infrastructure will develop rapidly in the ports concerned.

“In our view, there is a high probability that this will become a legal requirement within the lifetime of the vessel. The commercial and technical effort of a direct implementation of the shore connection is significantly lower compared to a retrofit. Last but not least, the shore connection is a central part of the zero-emission concept of the Orca vessels.”

“In our view, there is a high probability that this will become a legal requirement within the lifetime of the vessel. The commercial and technical effort of a direct implementation of the shore connection is significantly lower compared to a retrofit. Last but not least, the shore connection is a central part of the zero-emission concept of the Orca vessels.”SAL’s Orca class shore power connection sends a “clear signal” to the market that SAL Heavy Lift, as part of the Harren Group, is committed to zero-emission shipping, Christiansen said. “We know from our customers that they are extremely interested in climate-friendly transport concepts. The Orcas set the bar for future heavy-lift vessels.”

Tramping Troubles

One of the stumbling blocks of shore power for MPVs is that the traditional tramping routes mean that there isn’t the same security of port calls as for, say, container ships. This means that operators cannot be sure that every port they call at will be able to provide shore power, undermining the investment in the infrastructure on the ships.

Christiansen acknowledged that the future routing for the Orca class could well be influenced by ports that have shore power connections. “When it comes to choosing one berth or another, this could certainly become a selection criterion in the future. But we rather hope that the chicken-or-egg question will be answered soon and that it will now be the turn of the ports and the industry to react and develop infrastructure and standards.”

As heavy-lift and MPV vessels are not the largest electricity consumers in the port, Christiansen added that when it comes to reducing emissions in ports, it is logical that heavy-lift and MPV vessels have not, so far, been a priority and that it is understandable that infrastructure in the cruise, ferry and container segments has been developed first.

But “heavy-lift and MPV are now next in line,” he said.

Some smaller ports are taking the first steps towards shore power connections in readiness for calls from niche ships. In May 2023, Royal Roos’ green powered shore power connection for seagoing vessels berthing at Merwehaven in Rotterdam plugged in its first vessel: ALP Maritime Services’ DP II anchor handling salvage tug ALP Winger.

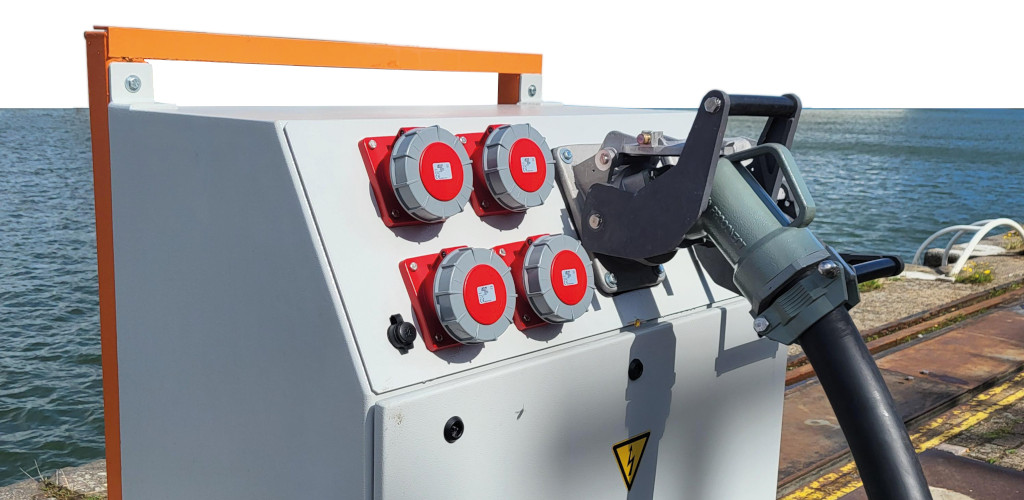

Powered via 1,500 m2 of solar panels on the roof of a building and a 1,000 kVA transformer, the Royal Roos shore power installation is purposely built for smaller seagoing vessels and tailored to their operational requirements. The power connection can also be used to load battery containers and e-trucks.

Speaking to Breakbulk, Royal Roos’ Veronica Breed said that location and convenience played a part in the decision to install the shore power infrastructure: “We are situated in the Merwehaven, in a former fruit cold storage renovated into workshops and offices including a quayside. The infrastructure of the old and new building combined with our day-today business - marine engineering, seagoing vessel maintenance - gave Fulko Roos, founder and director of Royal Roos, the idea to use this for a shore power facility for seagoing vessels mooring at the Merwehaven.”

She added that a successful application for a regional funding program, REACT EU - from the ‘Kansen voor West’ partnership program of the European Fund for Regional Development, offered an EU subsidy for the installation. “The REACT EU program funded up to 60 percent of cost and of course this helped a lot in realizing this first installation.”

Sustainability Goals

The installation also supports Royal Roos’ own sustainability ambitions. “As a company operating in the maritime industry, we are very aware of the need to make the sector more sustainable and future proof. Our main goal is to make our clients’ assets fit for 2030/2050 and beyond,” Breed said.

“Sustainability and green power are the way forward; there is a major shift happening from fossil to renewable energy, from production from virgin materials to production by smart reusing of materials, etc. and we have and want to be part of this transition, not only to stay relevant in this business, but also because we want to make a difference in the maritime industry.”

Merwehaven east side allows mooring for vessels up to 225 meters long, 30 meters wide and maximum 40,000 deadweight-tons. Harbor depth is -9.65 meters Amsterdam Ordnance Datum.

Typically, anchor handling, towage and offshore supply vessels call at Merwehaven and so Royal Roos has matched its first shore power installation to those type of vessels and their average power demand.

Royal Roos has plans to expand its shore power connections to be able to provide shore power to vessels with a power demand up to 1,000kW as well as being able to provide shipside shore power modifications.

“Furthermore, as the current shore power installation is our own design, we market this as a product - we design, produce and deliver shore power installations including ship side modifications for seagoing vessels in any configuration up to 11kV and 2MW, 50/60 Hz,” Breed said.

Whether through legislation or innovation, shore power is coming to the breakbulk market. Partnerships with secondary ports and securing government funding will ensure that the MPV market makes up for lost time in the coming years.

The challenge of zero carbon shipping will be the focus of a mainstage panel session at Breakbulk Americas 2023. “The Journey Towards Decarbonization: Progress, Challenges and Opportunities”, moderated by Maersk Project Logistics’ Dennis Devlin and featuring expert speakers from the American Transportation Research Institute, Swire Projects and the US Maritime Administration will take place on September 27 from 4:00pm–4:45pm.

Check out the full main stage agenda for this year’s event, happening on 26-28 September at the George R. Brown Convention Center in Houston, Texas.